-

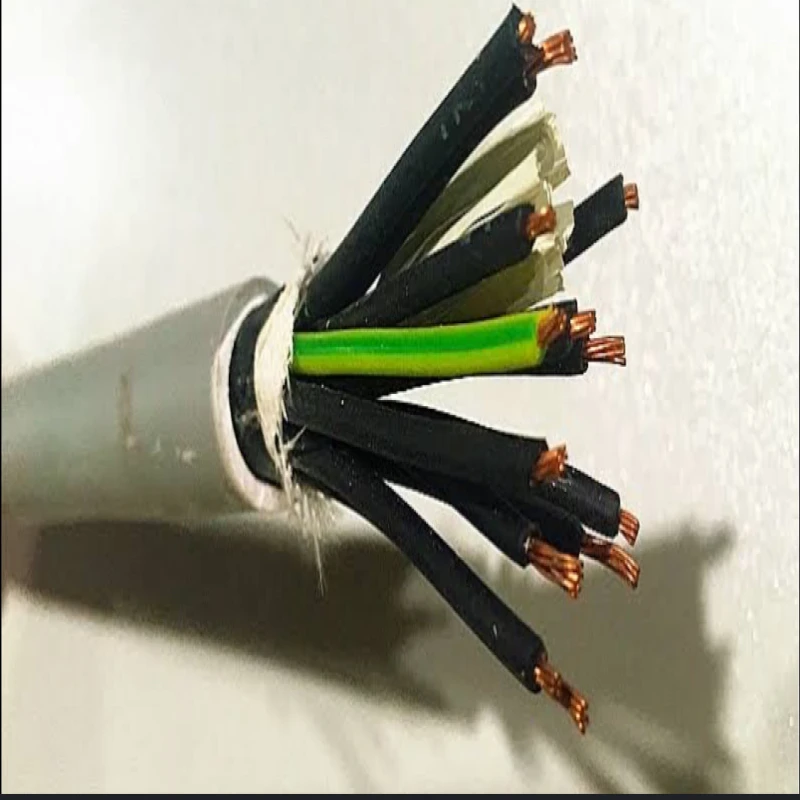

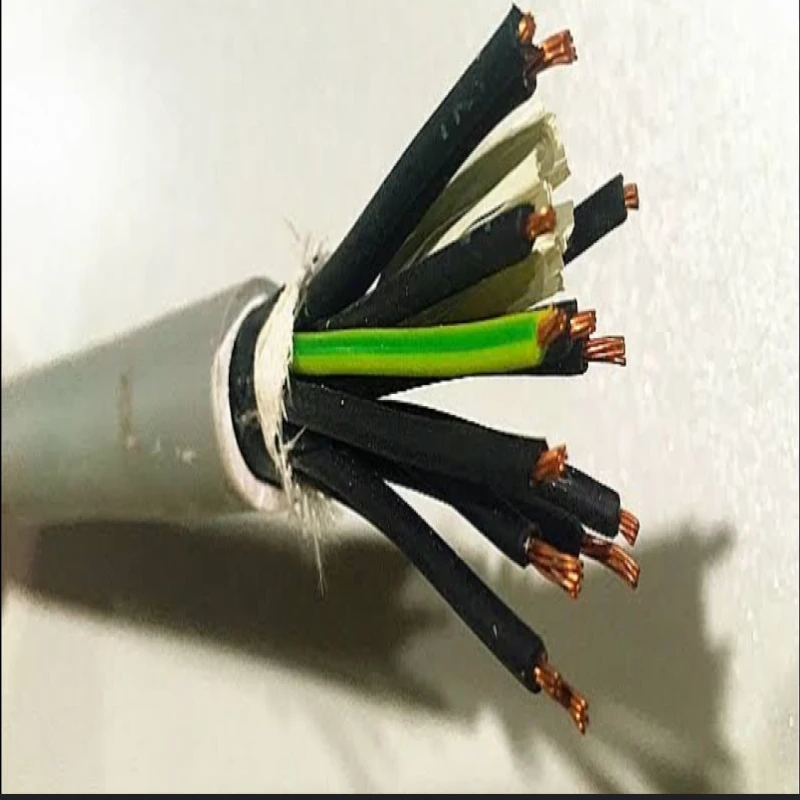

The core of the cable is made of stranded copper (or sometimes aluminum) with a cross-sectional area of 2.5mm².

-

Each core is individually insulated with a material like PVC or XLPE (Cross-linked polyethylene), providing electrical isolation between the conductors.

-

The entire assembly of 12 cores is then enclosed in an outer sheath, often made of PVC, which provides mechanical protection and environmental resistance.

-

Some control cables may include an armour layer, typically steel wire (SWA), for added mechanical protection, especially for underground or harsh environments.

-

These cables are widely used in control systems, automation, and instrumentation applications where multiple signals or power circuits need to be managed simultaneously.

-

The multi-core design allows for efficient transmission of various signals, and the 2.5mm² conductor size provides adequate current-carrying capacity for many control applications.

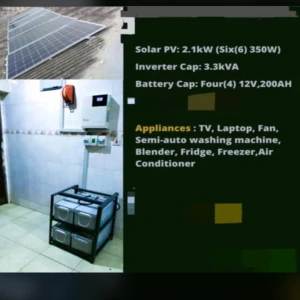

APPLIANCES

APPLIANCES ELECTRIC AND POWER

ELECTRIC AND POWER ELECTRONICS

ELECTRONICS FOOD

FOOD GADGETS

GADGETS KITCHEN

KITCHEN SOLAR SOLUTIONS

SOLAR SOLUTIONS