-

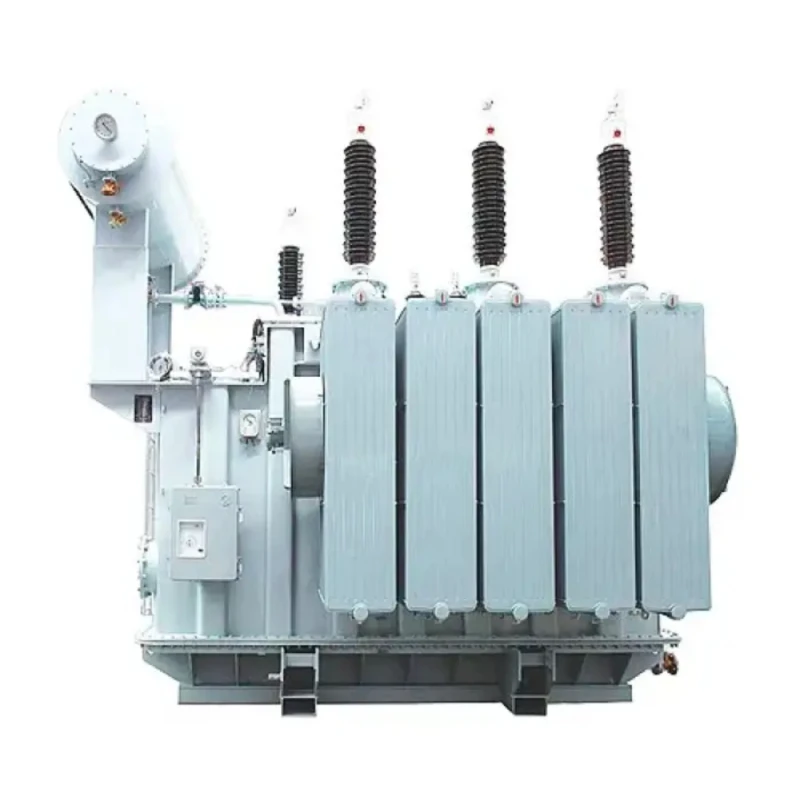

These are the primary insulating units, typically made of porcelain, and are connected in strings to achieve the required voltage withstand.

-

These fittings connect the individual disc insulators to each other and to the supporting structures, allowing for flexibility and ease of assembly.

-

Various hardware components, such as clamps, yokes, and connecting links, are used to secure the insulators and conductors.

-

Porcelain is an excellent insulator, preventing the flow of current between the conductor and the supporting structure, thus preventing short circuits and electrical hazards.

-

Insulators support the weight of the conductors and withstand the mechanical stresses caused by wind, ice, and other environmental factors.

-

The design of the insulator provides a sufficient creepage distance to prevent surface leakage currents, especially in environments with high humidity or pollution.

-

The flexible nature of the suspension string helps to dampen vibrations and reduce conductor fatigue.

-

The most common material for disc insulators due to its excellent electrical and mechanical properties, as well as its resistance to environmental factors.

-

Typically made of galvanized steel for corrosion resistance and mechanical strength.

-

33kV disc insulators are widely used in overhead power lines to support conductors and prevent electrical faults.

-

They are also used in substations to insulate equipment and ensure safe operation of

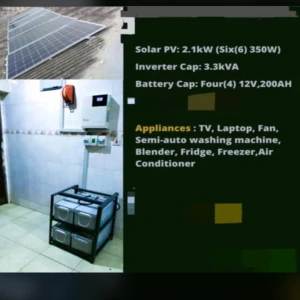

APPLIANCES

APPLIANCES ELECTRIC AND POWER

ELECTRIC AND POWER ELECTRONICS

ELECTRONICS FOOD

FOOD GADGETS

GADGETS KITCHEN

KITCHEN SOLAR SOLUTIONS

SOLAR SOLUTIONS