-

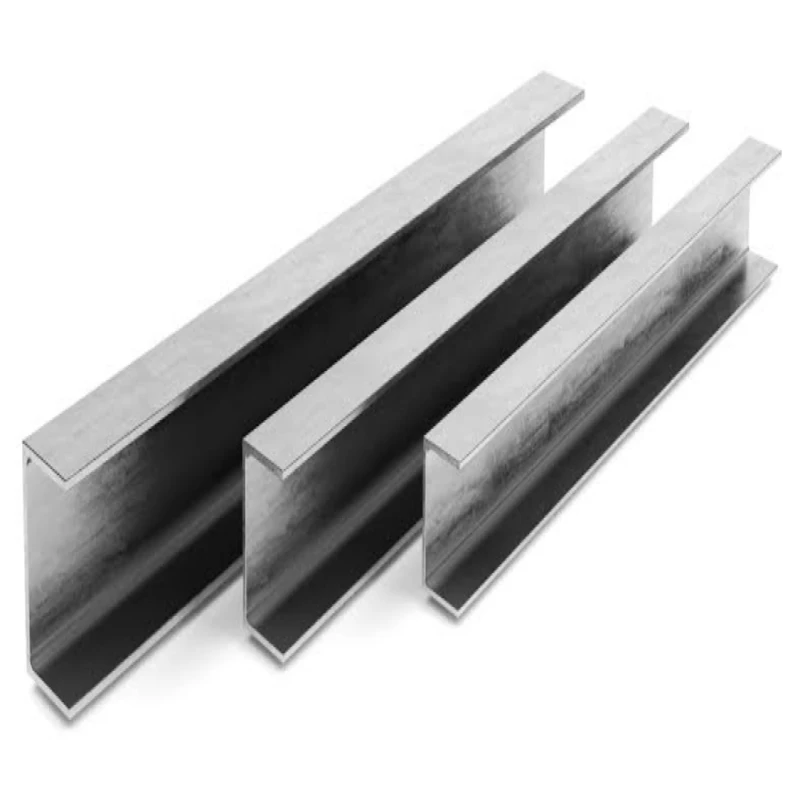

Typically made from hot-rolled steel, often A36 grade, providing a balance of strength and cost-effectiveness.

-

The hot-dip galvanizing process involves submerging the steel channel in a bath of molten zinc, creating a durable and corrosion-resistant coating.

-

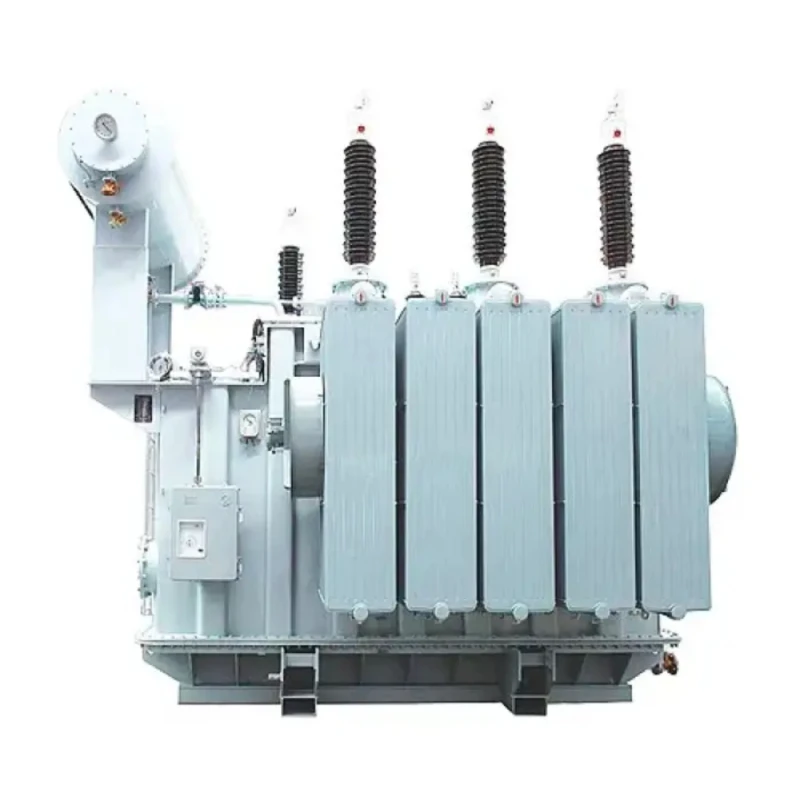

Designed to withstand the high voltage (33kV) used in power transmission and distribution systems.

-

Used as a structural support component, such as cross-arms, on power poles and towers to hold and secure electrical equipment and conductors.

-

The galvanized coating provides long-term protection against rust and corrosion, even in harsh outdoor environments.

-

The steel channel itself offers the necessary strength and rigidity to support the weight and forces associated with power lines and associated hardware.

-

Galvanized channel iron can be readily cut, machined, and welded using standard steel fabrication methods.

APPLIANCES

APPLIANCES ELECTRIC AND POWER

ELECTRIC AND POWER ELECTRONICS

ELECTRONICS FOOD

FOOD GADGETS

GADGETS KITCHEN

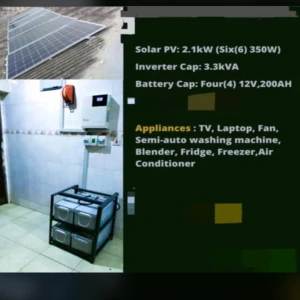

KITCHEN SOLAR SOLUTIONS

SOLAR SOLUTIONS